How to distinguish natural stone from inferior

Because stone is a natural material, it has many inevitable defects, and the defective stone products are unacceptable to customers, so many factories will cause huge waste and loss. Some stone factories will sell these secondary products as first-class products (A-class products) to customers after certain treatment, of course, the price is relatively cheap. Therefore, we must open our eyes to confirm each piece of qualified stone products during factory inspection. Otherwise, it is the customer's claim, and it is the loss of the customer.

Generally, the methods of stone factory to process the inferior stone into the first-class stone are as follows:

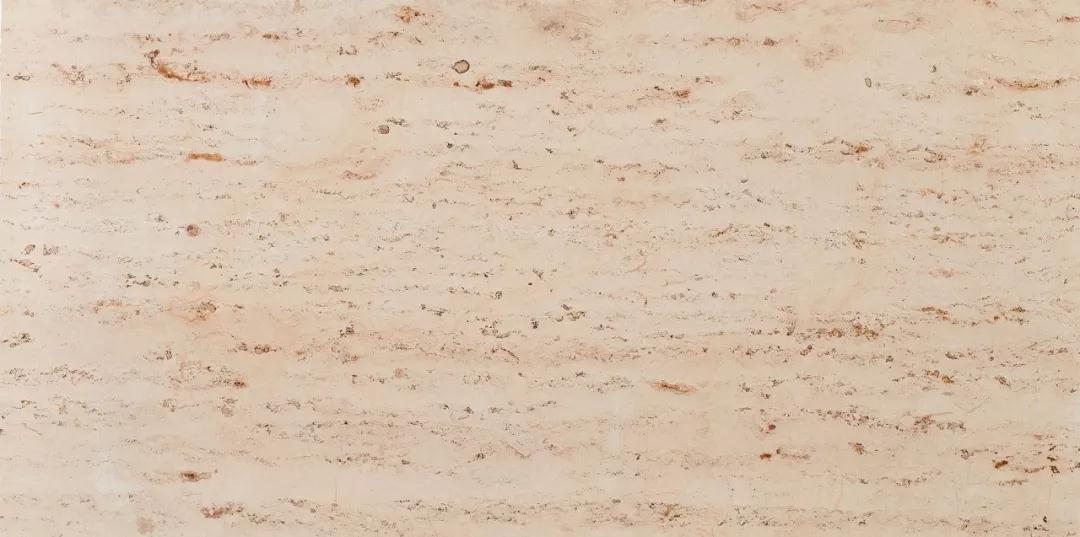

1. Use wax to repair the stone with holes on the board surface (especially granite)

It's not safe to do so. The correct way is not to make up wax, but to make up epoxy resin with the same or similar color as the stone board. Use wax to repair holes. Once the wax falls off in the middle of the process or dissolves due to factors such as sun exposure and high temperature environment or fumigation enclosed in the container, the holes will still appear at last. The board surface was very good when the goods were inspected, but there are holes on the board surface of the customer.

How to distinguish the stone repaired with wax?

At this time, as long as we pay attention to some unnatural crystals (crystal particles) on the stone board, those are often paraffin fake.

2. Because the polishing degree is not up to the standard, oil, wax and film are used to increase the glossiness of stone.

Due to their own processing technology or cost considerations, some stone processing plants do not grind the stone to the glossiness that meets the contract standards or requirements, so they use the methods of polishing oil, waxing and coating light film to increase the glossiness of the stone plate surface, so as to make it conform to the required luminosity of the contract (generally above 90 degrees). The effect is also very bad, such as oiling and waxing. It may not be ready for installation (or the installation process). Although the coating and grinding are better, once the smooth film is worn out, it will also be exposed. For some orders with delivery time, it is quite dangerous, and the money and goods may be empty.

How to distinguish the polished stone products?

Generally, the back and side of the oiled stone products will have oil stains, or even oil spots; the waxed stone will look at the board in a different way. You can bake the board with matches or fire. If there is waxing, it will be copied out to reveal the original face of the stone; as for the polished stone, although the glossiness is very high, the strength of the general film is not good, and it is easy to be worn. See scratches on the light.

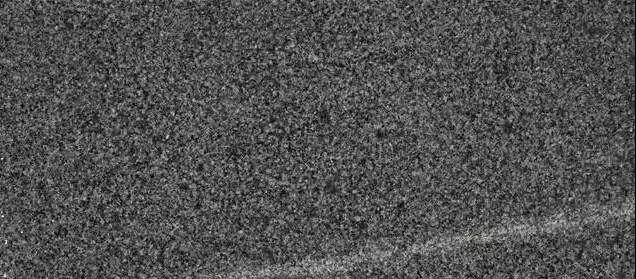

3. Treatment of defects such as black gallbladder and stain

The black gall spots of stone materials are generally treated with strong oxidant, which is the same in most factories. But there are differences between good quality factories and poor quality factories. The factory with good quality will deal with it after rough grinding, then wash it clean without any oxidant residue, and then conduct fine grinding. In the factory with poor quality control, the stone with defects such as black gall color plate shall be polished first, and then the stone shall be treated. The strong oxidant shall be applied on site and washed on site, and the stone that can be treated shall be accepted by quality inspection. In fact, this is also problematic. First of all, due to the strong acid or alkali corrosion of the polished plate, the surface of the plate is damaged and the glossiness is reduced. Secondly, when washing strong oxidants on site, they should be packed in the box, which will result in unclean washing of strong acid or strong alkali on the stone plate, and the residual strong oxidants will continue to react with oxidation, resulting in problems such as color difference and contrast white, etc., which will damage the plate surface. Moreover, because of being washed by water, these strong oxidants will flow to other places and cause secondary pollution, and the pollution range is often larger than the place where they are applied. Much larger.

How to deal with the treatment of stone with defects such as black gall and stain?

For this problem, we'd better check the goods when there's plenty of time. If there's any stain or color gall that needs to be handled, it must be cleaned and then sent to be polished.

4. Dye the color difference stone, or use other stones to dye instead.

For dyed stone, first of all, it needs to be recognized by customers. Never use dyed stone as a first-class product. For and even if it is dyed stone should be dyed evenly, color fastness is good, can not fade.

So how to distinguish dyed stone?

The color of the dyed stone surface will be more gorgeous and unnatural. If we break the plate, we will find that the dye penetration layer can be seen at the fracture of the plate. There are also natural stones that can be dyed in general. Their stone quality is not good. They are all stones with large porosity and high water absorption (this will affect the physical and technical performance of stone, which is prone to accidents). Generally, they can be distinguished by percussion. The sound of compact stone is crisp, while the sound of loose stone is dull. There is also the same kind of natural stone, after dyeing, its glossiness is lower than that of the stone without dyeing, which is a little dim.