How to reduce the noise produced in stone processing?

No matter what equipment and processing technology are used in the process of stone processing, there will inevitably be noise, especially in the case of irregular operation or overload operation, the strong and harsh noise will seriously affect the surrounding environment. The harm caused by noise is relatively large, especially in the following aspects:

1. Working in a strong noise environment for a long time can cause noise induced deafness.

2. Affect people's normal work, study and daily life.

So how is the noise generated in the process of stone processing? It mainly comes from the noise of tooth tip, vibration of saw blade and material friction.

Tip noise: when the saw blade operates at high speed, the sawtooth of the saw blade interacts with the surrounding air, resulting in the noise caused by the pressure fluctuation of the air.

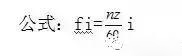

The sound power of the tip noise is directly proportional to the third power of the diameter of the saw blade and the linear speed of the saw blade. When the rotating speed is lower, it is directly proportional to the third power of the linear speed. The frequency of the tip noise can be calculated by the following formula:

Where: fi - noise frequency of tooth tip, i.e. the number of times the saw tooth hits the air particle per second, (Hz)

Z - number of teeth of saw blade

N - rotation speed of saw blade shaft (R / min)

I-harmonic sequence I = 1, 2, 3...

When the saw blade rotates, each tooth tip generates a monopole radiation flow, which is periodically discharged out through the SAW seam of the workbench. Due to the drastic change of air flow pressure, exhaust noise is generated, and the rising power of exhaust noise increases sharply with the increase of the linear speed of the saw blade, which is proportional to the 6th power of the air flow speed. When the online speed is small, it is proportional to the 5th power, the exhaust noise is generated. The frequency is:

式中:fi—排气噪声频率,(HZ)

z—锯片的齿数(个)

n—锯片轴的转速(r/min)

i—谐波序号 i=1、2、3……

在锯片高速旋转时,每当涡流分离的频率与锯片的固有频率相近时,就发生共振,便发出“尖叫声”,其频率为:f = z fr

式中:z—锯片的齿数(个)

fr—轴回转频率(HZ)

锯片属于薄壁件,其刚性一般较差,在外力的作用下很容易产生振动,由于振动便容易产生物料的摩擦,因此该类的噪音也就随之产生。

那么可以采取那些有效措施能降低噪音的产生呢?

从锯片基体的结构设计上达到减噪目的

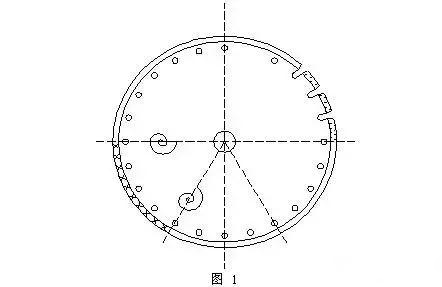

1、 在不破坏锯片的平衡及所需刚性的条件下,可在锯片基体上均匀布置几个相同尺寸的小孔。在孔中高阻尼合金或非金属物,这样可以减弱锯片弹性振动的传播,消除高频噪音。

2、 同样在不破坏锯片刚性的情况下,在锯片基体上设有若干个等间距沿不同半径基圆分布的曲线(或直线)型不同几何形状的消声缝隙,消声原理是结块与被切割材料间由于摩擦和撞击所产生声波在基体上传播受到阻尼,使其余不参与被切割材料接触部位上的音频共振减少,从而达到了降低噪声强度的目的。

如图1:

3、 复合结构

复合阻尼结构在减振降噪工程结构上也开始应用,它是薄弹性材料将几层板粘结在一起的具有高阻尼特性,并保持金属板材料强度的约束阻尼层结构,阻尼层厚度为0.10mm。在常温和高温(80—100℃)下具有良好的阻尼特性,它对振动能量的消散,从一般普通弹性变形作功力消耗,提高为高弹性体变形的做功消耗,使变形滞后应力的程度增加,另外,这种约束阻尼结构拉压变形所消散的能量,消耗因子一般在0.3以上,最大峰值可在0.85,并且是有宽频带控制特性,在很大的频率范围内起到抑制峰值的作用,锯片基体常用的复合阻尼层结构为2层。

利用复合阻尼结构的锯片基体有如下特点:

(1) 锯片的校平及应力的调整难度很大;

(2) 生产效率较低,成本较高;

(3) 加工处理技术不当,基体会缺乏轴向刚性。

安装及使用方法降噪

1、 夹盘改造降噪

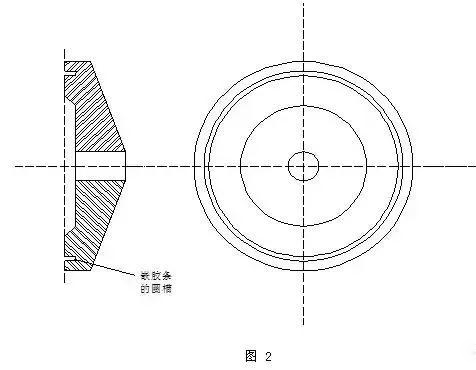

(1) 在不影响锯切高度前提下,应尽量加大锯片的夹盘直径,这样可以提高锯片刚性,减少弯曲振动,对降低振动噪声是及其有效的,实验研究证明,当夹盘直径加大到锯片直径的3/4倍时,减噪最佳。

(2) 为了增加锯片的弹性,使其受力均匀,在夹盘上开一圈槽,嵌入橡胶条或软金属。

如图2:

2、 加装隔声罩

用隔声罩来降低锯片加工时的综合噪声是行之有效的,罩壳用钢板制成,内涂阻尼材料、吸声材料,选择超细玻璃棉,衬一层玻璃布。并用穿孔板护面。罩壳、吸声材料、穿孔板相对固定以防止设备运转造成系统共振引起新的噪音。

措施与能达到的降噪效果:

(1) 基体采用复合结构可以降噪10分贝左右

(2) 减振法兰盘可以降噪 3分贝左右

(3) 基体采用消音孔或消音缝 5分贝左右

(4) 整体隔音罩 10分贝左右